Dymstec’s business scope includes project-based supply and delivery of projects including electromagnetic shielding rooms, technical advice on EMC chambers, simulation, design, manufacturing, installation, maintenance, and integration of test equipment for certification testing.

We continuously apply quality management system by applying ISO 9001: 2018 quality management system to each process step, and systematically establish project performance change factor management to achieve the final goal of the target management system established at the initial stage and We are working on a high quality action plan while operating together.

-

Simulation

- Optimize chamber modeling

- Pre-validation of performance

-

Design

- Optimized design for deployment purposes and applications

- Minimize design errors

-

Fabrication & Construction

- Construction know-how

- Minimize technical and economic losses

-

Performance Evaluation

- Retaining technical personnel and measurement facilities for SE performance evaluation

- Active response to performance changes

-

Completion

- Deploy high-performance EMC chamber

- Acceptance test of the state-run certification authority

-

Maintenance

- Continuous follow-up management

- Extended performance guarantee

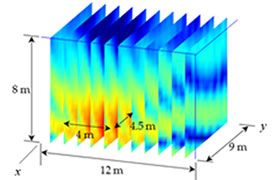

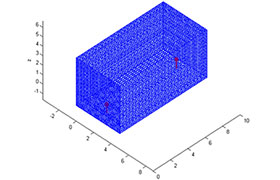

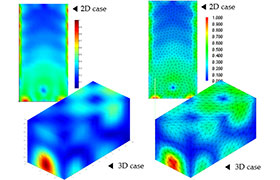

Perform Optimization Tasks Through Chamber Modeling and Performance Simulation

The final specification of EMC chamber to be constructed is determined by using the simulation tool of DRT (Determined Ray Tracing) technique jointly developed by Korea Electromagnetic Society, Dynamic Shielding and KAIST, We are maximizing customer satisfaction by drastically reducing time and money.

By tracking the 1st, 2nd and 3rd reflected waves by substituting the selected Absorber’s characteristic value and the Loss Factor of the Test Antenna, the electric field strength distribution and performance of the chamber can be predicted through numerical analysis such as NSA, SVSWR, and Field Uniformity. High performance simulation tool.

More than 20 years of Experience in EMC Chamber Construction

More than 20 years of skilled electromagnetic shielding facility construction know-how, more than 80% of the company’s organization consists of RF, EMC, and EMP protection specialists to identify possible problems in the installation process. Is composed of professional construction technicians with skill and experience to build high quality electromagnetic shielding room satisfying customer requirements.

In addition, we have made continuous efforts for long-term performance preservation management through regular follow-up management, and the performance of the electromagnetic shielding room and the electromagnetic compatibility test room that have been delivered already meet 100% of customer requirements.

Self-operating EM Shielding Room for R&D Purposes and Conducting Door Reliability Tests

We are building and operating EM shielding rooms for research and development purposes to meet more economical and high quality shielding door production, customer requirements, and operational comfort.

Korea Institute of Machinery and Materials RS-KIMM-2013-0195 Electromagnetic shielding doors of various standards produced based on the reliability test standards for electromagnetic shielding doors, gap variation, shielding performance, opening and closing performance, static load resistance, residual displacement, deflection, and service life We are constantly making efforts to realize quality assurance and customer satisfaction by conducting performance tests.

Shielded Component Manufacturing Infrastructure and Skilled Production Technicians

We are equipped with manufacturing infrastructure and skilled production technicians for the production of shielding panels, electromagnetic shielding doors and EMP shielding racks. Each shielded component process strictly adopts the ISO 9001: 2018 quality management system, and uses carefully selected materials for long-term performance guarantee based on precise design. We minimize the manufacturing quality and defects.

By operating the direct production plant and establishing a smooth material procurement and product production plan, it is responsible for the successful completion of the project within the project execution period, and can promptly respond and support customer requests related to change factors and product quality.

Maintenance System

The technical support department supports the stable operation of target facilities by establishing a precautionary and follow-up system for failures and problems.

Maintenance step-by-step planning

- Step 1 : Problem is generated → Problem is received and visited → Problem type analysis

- Step 2 : Review for repair and replacement

- Step 3 : Suggest solutions → resolve problems → check and report results → Manage problem types

| Regular Inspection | Occasional Inspection | ||

|---|---|---|---|

| Schedule | Once a month | Schedule | In case of a problem |

| On-site inspection | Inspection of project team on site | On-site inspection | Inspection of technical sales |

| Technical support | Technical support team support | Technical support | Technical support team support |

| Paid Maintenance Costs and Scope | |||

| Decision after separate consultation after expiration of the free maintenance contract | |||

Equipment Status Required for Site Validation Test

| Test Type | Equipment | Company (Freq.) | Model No. (Freq.) |

|---|---|---|---|

| General | Signal Generator | Keysight | N5173B |

| Spectrum Analyzer | Keysight | N9010A / N9020A | |

| Spectrum Analyzer | R&S | ZVBB | |

| SE | PreAmp | Sonomia Instrument | 310N |

| Agilent | 8449B | ||

| PowerAmp | AR | 100A250B (10kHz - 250 MHz) | |

| EXODUS | (27MHz - 1GHz) | ||

| EXODUS | (0.7GHz - 4GHz) | ||

| EXODUS | (2.5GHz - 8GHz) | ||

| EXODUS | (4GHz - 18Ghz) | ||

| Antenna | Schwarzbeck | HFRA 5149 | |

| Schwarzbeck | VAMP 9243 | ||

| Schwarzbeck | VHBC 9133 (+9106) | ||

| Schwarzbeck | VHLP 9108 | ||

| Schwarzbeck | BBHA 9120D | ||

| FU | PowerAmp | EXODUS | (27MHz - 1GHz) |

| EXODUS | (0.7GHz - 4GHz) | ||

| EXODUS | (2.5GHz - 8GHz) | ||

| EXODUS | (4GHz - 18Ghz) | ||

| Antenna | Schwarzbeck | VHBC 9133 (+9106) | |

| Schwarzbeck | VHLP 9108 | ||

| Schwarzbeck | BBHA 9120D | ||

| Powermeter | Agilent | E4418B | |

| Powersensor | HP | 8481A | |

| Coupler | AR | DC3510A | |

| AR | DC7144A | ||

| Bonn-elek | BDC2080-40 | ||

| Probe | AR | FP5080 | |

| AR | FL7218 | ||

| E Field Monitor | AR | FA7218 | |

| sVSWR | PreAmp | Sonoma Instrument | 310N |

| Agilent | 8449B | ||

| Antenna | Seibersdof | POD 16 | |

| Seibersdof | POD 618 | ||

| Auto Positioner | Seibersdof | SPA1 | |

| NSA | Antenna | Schwarzbeck | VHBB9124 |

| Schwarzbeck | VULP9118A | ||

| ETC | Attenuator | Agilent | 8491B |

| Cable | Huber-Shuner |